Objects of desire

Inside the winning designs of the BOAT Artistry & Craft Awards 2025

PHOTOGRAPHY: BEN HARRIES, BLUEIPROD, NATURE SQUARED, EVA MECHLER

Designers and shipyards often take centre stage when a yacht is launched – but behind each awe-inspiring project, there are talented makers in the wings. Holly Margerrison meets the winners of the BOAT Artistry & Craft Awards and uncovers their inspirations, passions and processes.

THE JUDGES

Deborah Pocock LVO, CEO of QEST; Lay Koon Tan, co-founder of Nature Squared; Adrian Sassoon, contemporary art dealer; Andrew Winch, founder of Winch Design; Jay Rushton, CEO of Parkway England; Christopher Whale (chair), group creative director of BOAT International Media

CÉLINE ALEXANDRE

Excellence in Craftsmanship

NOMINATED BY Reymond Langton Design

FOR decorative panels on Kismet

PORTRAIT: Iris Brosch

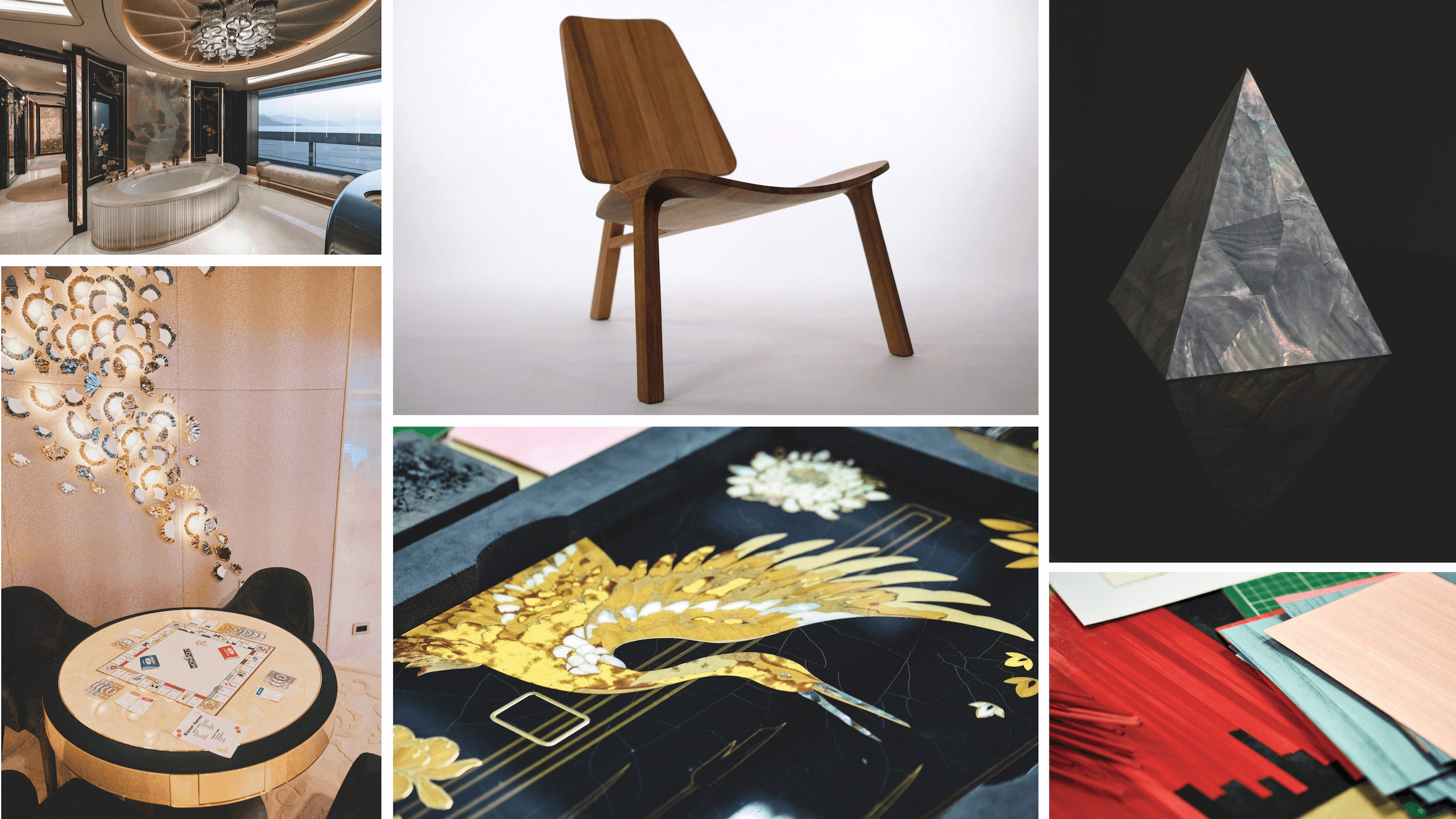

Step on board 122-metre Lürssen Kismet and you’ll find the maximalist, fantastical, awe-inspiring aesthetic that has made the yacht one of the hottest talking points in the yachting community over the past year. There are so many creative spaces and themes that even the engine room gets its own name; it’s a yacht that cannot be contained or put in a box. It’s fitting, then, that designer and co-founder of the Reymond Langton studio, Pascale Reymond, called on a host of multidisciplinary artists to create what she has dubbed a “cathedral of design”.

One of these experts is Céline Sorigué, artistic director and co-founder of Céline Alexandre, who was commissioned to create custom-designed decorative panels for the beauty room on board. Drawing on Sorigué’s haute couture background (as artistic director, she spent 12 years at the helm of Atelier Dynale, a studio known for its expertise in creating textured fabrics for haute couture), the panels depict a flight of ginkgo leaves, paying homage to the uniquely shaped symbols that are representative of hope and strength in Chinese culture, and survival and peace in Japan.

CÉLINE ALEXANDRE

Excellence in Craftsmanship

NOMINATED BY Reymond Langton Design

FOR decorative panels on Kismet

PORTRAIT: Iris Brosch

Step on board 122-metre Lürssen Kismet and you’ll find the maximalist, fantastical, awe-inspiring aesthetic that has made the yacht one of the hottest talking points in the yachting community over the past year. There are so many creative spaces and themes that even the engine room gets its own name; it’s a yacht that cannot be contained or put in a box. It’s fitting, then, that designer and co-founder of the Reymond Langton studio, Pascale Reymond, called on a host of multidisciplinary artists to create what she has dubbed a “cathedral of design”.

One of these experts is Céline Sorigué, artistic director and co-founder of Céline Alexandre, who was commissioned to create custom-designed decorative panels for the beauty room on board. Drawing on Sorigué’s haute couture background (as artistic director, she spent 12 years at the helm of Atelier Dynale, a studio known for its expertise in creating textured fabrics for haute couture), the panels depict a flight of ginkgo leaves, paying homage to the uniquely shaped symbols that are representative of hope and strength in Chinese culture, and survival and peace in Japan.

IRIS BROSCH Céline Alexandre

IRIS BROSCH Céline Alexandre

Somewhat at odds with the maximalist spaces on board, the beauty room serves the function one would expect: a soothing, subtle and soft environment. Scratch beneath the surface though, and you understand the intention behind each layer; in fact, the artist investing him or herself wholeheartedly into the making process is something Sorigué is emphatic about when designing.

She suggests a big part of the process is in the preparation, and used hand drawings to capture the movement of each individual ginkgo leaf. The studio team then used intricate layers of paint, varnish and metallic powder mixes over her drawings to bring softness, elegance, refinement and depth to the panels. The resulting trompe-l’oeil effect was further enhanced by gold leaf engraving.

“YOU HAVE TO DO THINGS WITH FEELING IF YOU WANT YOUR WORK TO RESONATE”

Sorigué references artist Mark Rothko as a key inspiration. “His works are built on layers and overlays of colour. Colour is an infinite field that requires true mastery. When you look at his works, you are drawn into a deep meditation.” The panels took the studio team a painstaking 400 hours to create and employ various painting styles, techniques and intricate layers of paint, varnish and delicate gold leaf engraving.

In this world of haute couture, precision and technicalities, does Sorigué ever leave room for error? “Nothing in life goes exactly like you would like,” she says, comparing it to the fall of ginkgo leaves, which she used as a symbol of freedom. “In the painting it was possible to do something else, to manage this fall because it is a fall of ginkgo, like in life.”

Of course, errors did occur, but Sorigué and her team would find new ways of doing things, of saying, “OK, this didn’t go right. What can I do? We’ll do it another way.” She likens design to a whole-body process like meditation. “In the workshop I tell the team, ‘Put your body like this, maybe you’ll feel better.’ You have to do things with feeling if you want your work to resonate. You have to be in the painting.”

SILVERLINING

Outstanding Collaborative Creation

FOR marquetry panels on Kismet

PORTRAIT: Ben Harries

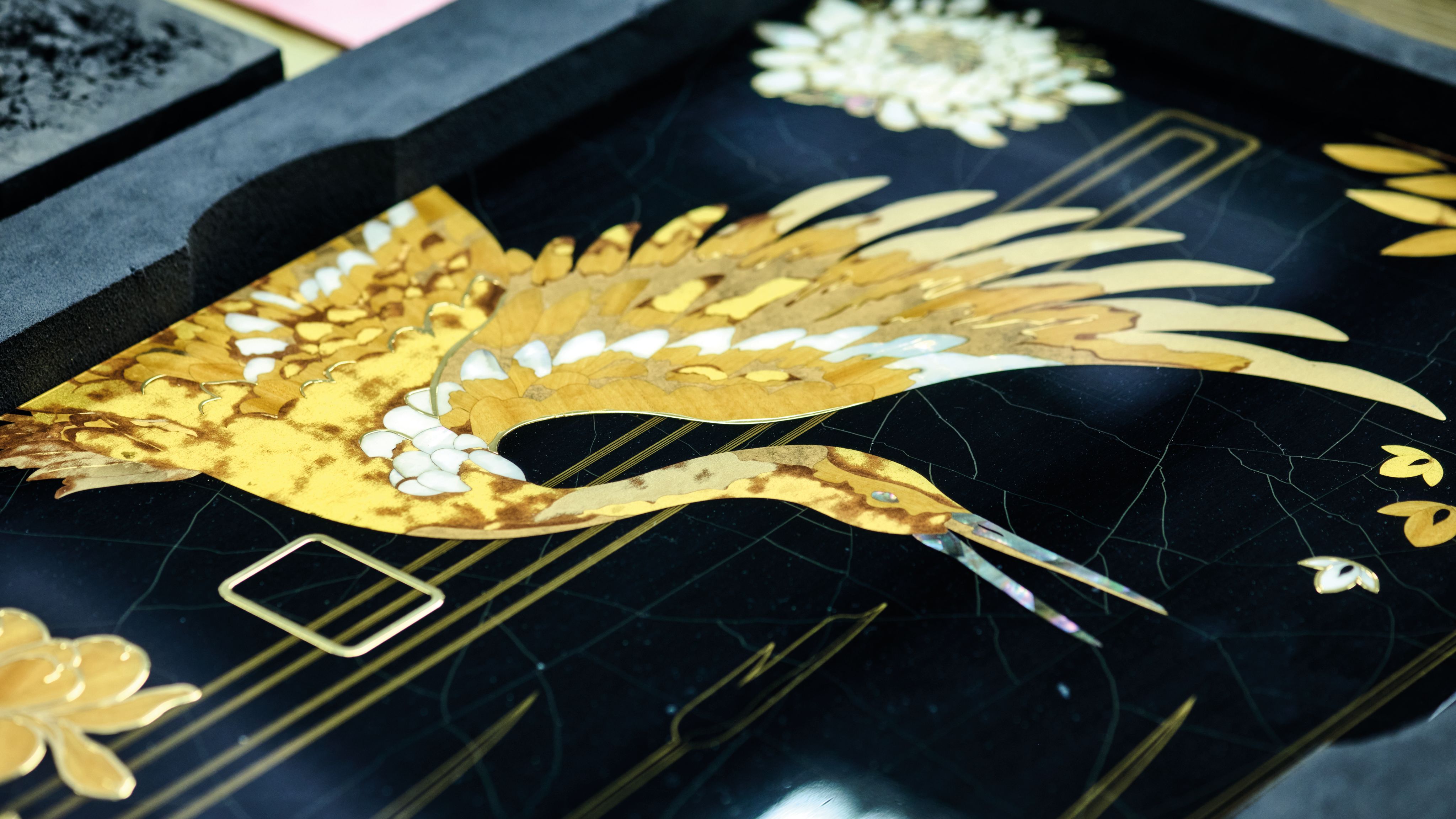

The award-winning marquetry panels on board the new Kismet took the Silverlining team almost 18 months to create, from the initial design concept through to installation. Apart from the leather department, every single department in the studio was involved, spending more than 6,000 hours of work and cutting a staggering 30,000 individual pieces of marquetry, creating more than 35 square metres in total. For each of the 29 panels, there were eight layers of meticulous detail.

Laser team leader and senior marquetarian Kevin Parry explains how the process started. The initial construction of the background panels began in the cabinetmakers’ workshop before being sent across to the marquetry department. The panels would then make their way back to the cabinetmakers, who would bond the marquetry down. He says: “The panels were veneered. Then they would come back to us, and we would etch the cracked porcelain-effect background layer on, and then they would go off and get worked on. After that, they’d come back. They were in and out of all the departments.”

SILVERLINING

Outstanding Collaborative Creation

FOR marquetry panels on Kismet

PORTRAIT: Ben Harries

The award-winning marquetry panels on board the new Kismet took the Silverlining team almost 18 months to create, from the initial design concept through to installation. Apart from the leather department, every single department in the studio was involved, spending more than 6,000 hours of work and cutting a staggering 30,000 individual pieces of marquetry, creating more than 35 square metres in total. For each of the 29 panels, there were eight layers of meticulous detail.

Laser team leader and senior marquetarian Kevin Parry explains how the process started. The initial construction of the background panels began in the cabinetmakers’ workshop before being sent across to the marquetry department. The panels would then make their way back to the cabinetmakers, who would bond the marquetry down. He says: “The panels were veneered. Then they would come back to us, and we would etch the cracked porcelain-effect background layer on, and then they would go off and get worked on. After that, they’d come back. They were in and out of all the departments.”

With so many processes, how many members were working on the panels at once? Parry explains: “Many people worked on this, but it was probably only two or three team members at any time in each department. It’s detailed and focused, so you can’t have too many cooks in the kitchen...”

The materials were worthy of mention themselves: the first layer was black bolivar wood, which was sealed to become a hard surface to work on. This was then etched into before it was flooded with lacquer to give the impression of actual cracks. Then, a layer of clear resin and more etching filled with the house-developed Dubai gold colour. Finally, the marquetry, a mix of satinwood, mother-of-pearl and gold, were applied on top.

And then there are the golds. “There was a mixture of moon, yellow and red gold leaf. There was also some faux metallic gold in there and black and white mother-of-pearl. Then there was the patinated metal resin.” Parry recounts how he had to attend a course to learn how to create the patina effect. “More resin was added before the decorative metal diametrics were added,” he continues. “Then, the final coat of resin and many layers of the gloss lacquer that was hand burnished to a mirror polish by our finishing team.”

BLUEIPROD The award-winning panels by the Silverlining team in situ in the owner’s en suite

BLUEIPROD The award-winning panels by the Silverlining team in situ in the owner’s en suite

The Silverlining team suggest there were a few testing moments, including not always knowing how the materials would react under the resin, and considering how the etched cracked resin would be affected by the moisture and temperature in the bathroom. The team has an accelerated weather chamber that they test their techniques on to predict how the panels behave

FOR EACH OF THE 29 PANELS CREATED, THERE WERE EIGHT LAYERS OF METICULOUS DETAIL

in moisture and ultraviolet radiation. The last panels were particularly challenging as they were curved, so the team had to pour the resin and bend the panels into shape.

The sanding was down to a mere tenth of a millimetre, and the stakes were high. Alex Davies from the finishing team explains: “You basically bond the marquetry or resin onto the panel, then you put it through a sander and sand the resin down 0.05 of a millimetre at a time, to get very close to the surface of the marquetry without sanding through and hitting it.”

“We’ve got one sample that went a little bit lower than it should have done. It created a cool effect and looks very antiqued. It’s an interesting finish,” notes Daniel Lloyd-Davies, research and development manager, with a laugh.

Eighteen months on, and the mammoth project is now out of the workshop for good, safely installed in its rightful home at sea. How will the team celebrate such a win? Will they all head to the pub? Or will it be a boardroom tea clink and a resounding sentiment that they never want to lay eyes on the panels ever again?! There’s a unanimous laugh before Lloyd-Davies says it will be a bit of both. “Onto the next one.” And so it continues...

POPPY PAWSEY

Emerging Artisan of the Year

NOMINATED BY Silverlining

FOR games table on Kismet

PORTRAIT: Ben Harries

Competing at the highest level of her craft comes naturally to Poppy Pawsey – but her successes haven’t always taken place in the workshop. Back in 2005, she joined the Royal Marines as a musician, embraced for her skills as a saxophonist and singer (rather than her violin playing, which, she notes, is “terrible”). It wasn’t long before she was singing solo at the Royal Albert Hall in front of 7,000 people, and performing at the Prince of Wales’ wedding, while learning the ins and outs of medical care and how to approach serious scenarios such as chemical decontamination behind the scenes. Tragically, however, her promising career came to an abrupt end when she suffered a life-changing injury.

“We were rehearsing for the Horse Guards Parade for Prince Philip’s birthday – a huge undertaking, she recalls. “It was a two-week rehearsal, constantly marching every day, and my right hip just went. I assume I pulled it because I’m short and you have to hit a certain stride. I think over the years my body just couldn’t take it anymore and it got to a breaking point.”

Pawsey made it through the real performance, but it became impossible for her to continue long term. She found leaving the military distressing. “You go into a room for medical discharge and come back out 10 minutes later with no job. That’s it,” she remembers. “They wrote one sentence about me: ‘The above, name, rank, is a drain on the band services resources and therefore needs to be medically discharged.’ It affected my mental health, as well as suffering with chronic pain.”

POPPY PAWSEY

Emerging Artisan of the Year

NOMINATED BY Silverlining

FOR games table on Kismet

PORTRAIT: Ben Harries

Competing at the highest level of her craft comes naturally to Poppy Pawsey – but her successes haven’t always taken place in the workshop. Back in 2005, she joined the Royal Marines as a musician, embraced for her skills as a saxophonist and singer (rather than her violin playing, which, she notes, is “terrible”). It wasn’t long before she was singing solo at the Royal Albert Hall in front of 7,000 people, and performing at the Prince of Wales’ wedding, while learning the ins and outs of medical care and how to approach serious scenarios such as chemical decontamination behind the scenes. Tragically, however, her promising career came to an abrupt end when she suffered a life-changing injury.

“We were rehearsing for the Horse Guards Parade for Prince Philip’s birthday – a huge undertaking, she recalls. “It was a two-week rehearsal, constantly marching every day, and my right hip just went. I assume I pulled it because I’m short and you have to hit a certain stride. I think over the years my body just couldn’t take it anymore and it got to a breaking point.”

Pawsey made it through the real performance, but it became impossible for her to continue long term. She found leaving the military distressing. “You go into a room for medical discharge and come back out 10 minutes later with no job. That’s it,” she remembers. “They wrote one sentence about me: ‘The above, name, rank, is a drain on the band services resources and therefore needs to be medically discharged.’ It affected my mental health, as well as suffering with chronic pain.”

BOTH THE TECHNICAL ABILITY AND THE EXCEPTIONAL LEVEL OF CRAFTSMANSHIP THAT PAWSEY ACHIEVED IN SUCH A SHORT PERIOD OF TIME IS WHAT AMAZED THIS YEAR’S JUDGES

BEN HARRIES Poppy Pawsey

BEN HARRIES Poppy Pawsey

After 12 years, she found herself back at square one, but with characteristic determination she soon found herself applying for the Invictus Games – an international sporting event for wounded, injured and sick service members and veterans. She was selected for Team UK in Toronto in 2017 and later for the Sydney Games in 2018, claiming bronze in both.

Looking for a new creative outlet, she had started making her own ceramics and jewellery, and it was thanks to a casual email introduction from her brother, praising her eye for detail, that she secured the job with Silverlining – a household name in the superyacht world, which is known for its bespoke furniture.

Fast forward two years and Pawsey is not only the proud creator of a beautiful, detailed games table on arguably the most anticipated yacht delivery of 2024, but also the deserved Emerging Artisan of the Year winner – and it was one of her very first projects, too. The games table had a twofold benefit for Pawsey. She learned most of her craft here: how to apply different dyes and finishes to various woods, colour theory and discovering a spectrum of colours.

Then, there was the process of making the table itself, which started as a 24-leaf starburst programming everything, selecting the veneer and the stain and then putting it back onto the laser – pressing a button and “holding her breath” – to physically cut the ginkgo leaves out of the background. Then, on to creating more ginkgo leaves out of more veneer and inlaying them into the marquetry. And that’s just the top of the table.

Pawsey was also responsible for making the chess and backgammon boards, the tiny butterflies inlaid in different veneers and varieties of wood that she would try to pick up with her scalpel but would ping off in every direction. Both the technical ability and the exceptional level of craftsmanship that Pawsey achieved in such a short period of time is what amazed this year’s judges, not to mention the resulting board.

For Pawsey, the award is a pleasing marker of her accomplishment in a new-found career – and a symbol of a new dawn of personal growth, too. Far from “a drain on resources”, she’s a valuable addition both to the studio and to the community of yachting artisans who recognize and appreciate each other’s work. “I think there’s this little fire that’s coming back, you know”, she says, with a glint in her eye.

Checkmate.

JUDGES COMMENDATIONS:

SABINA FAY BRAXTON

FOR headboard on board Kismet

Where are you based? In the north of Thailand in Chiang Mai. I moved here a few years back after starting my art textile and design business in Paris in the mid 90s and then Venice.

What is the studio’s speciality? It’s a technique extrapolated from the medieval technique of gaufrage. We call it “gilded gaufrage”. It consists of crushing the pile with heat to create an altobasso effect and infusing it with transparent inks and encrustations of metals.

Do you travel a lot for your work? Constantly, for exhibitions and to see clients. I design in situ to ensure the piece takes all aspects of space, light and spirit into account.

Coolest project you’ve worked on? Professor Albus Dumbledore’s cloak and office curtains in Harry Potter had its own kind of coolness.

BLUEIPROD The headboard on Kismet

BLUEIPROD The headboard on Kismet

Most exciting part of these projects? The initial concept stage, especially if it involves capturing the essence of another style or culture and ensuring it has meaning to the client.

Biggest reward and challenge as a specialised company? Being approached and acknowledged for what’s closest to one’s heart is the reward. The challenge might be to marry one’s vision with that of the client.

How long did the headboard on Kismet take? Two months, with two to three people working daily – me and two embroiderers.

EVA MECHLER

FOR Chair on board Fox

Where in the world are you based? My workshop is located near Zürich in Switzerland.

What is the studio’s speciality? My material of choice is the native species hardwoods harvested from sustainably managed forests in mainland Europe. I design and make my own Eva Mechler signature collections. I also collaborate regularly as a designer-maker using my studio and workshop to deliver commissions on behalf of international architecture and design studios.

EVA MECHLER The chair for the 35m Pendennis Fox

EVA MECHLER The chair for the 35m Pendennis Fox

Most exciting part of being commissioned for these projects? The technical challenge of making something original, complex and bespoke stimulates me. That and a positive cash flow!

Biggest challenge as a specialised company? Getting known and respected as an exemplary maker in the heady minuscule top division of superyacht builders and designers.

How long did the chair for Fox take in total? My prototyping of the leg construction detail on a three-leg stool in 2021 led to my sketching the chair in 2022. When Wolz Nautic turned up in 2024 with wood off-cuts from their deck installation on Fox, I used those off-cuts to make the Fox Chair, which itself required 60 hours of handcraft to make in my workshop.

Have you commissioned or created something beautiful for a superyacht that’s launching this year? If so, we want to hear from you. Apply for the 2026 awards directly via the link below, or if you’re concerned about an NDA, or need support from a designer but don’t have direct access to them, please email ciara.hutchison@boatinternationalmedia.com for assistance. Nominate now: boatint.com/baca