WORK IT

Turning a working boat into the comfort of the 46-metre Scintilla Maris

To create an expedition yacht that would withstand high latitudes, one adventurous owner chose a tough work boat and refitted her at a commercial yard. Sam Fortescue discovers how no-nonsense construction and a hands-on boss led to the comfortable, capable 46-metre Scintilla Maris

The smell of brill and turbot may be long gone, but the pedigree of an all-weather work boat is everywhere in evidence as Scintilla Maris begins her second life as a comfortable private yacht. Her proud Dutch-American owner sums it all up to a group of 100 guests who have gathered for the relaunch at Damen Maaskant’s shipyard at Stellendam, South Holland, which is the commercial arm of the Damen Shipyards Group: “She is one of the most solidly built, best handling sea vessels one could wish for. She can go anywhere anytime. The only limits are those of the people on board!”

DAMEN MAASKANT

DAMEN MAASKANT

Twenty years of trawling the North Sea for flatfish is proof enough of this, and it’s succinctly encapsulated in her former fishing name, Vertrouwen, meaning “trust”. “This was one of the largest boats built at Maaskant in 1989 as part of a series of eight,” the owner tells me as we seek shade under the boat’s freshly extended Portuguese bridge. “When she came up for sale during a decommissioning round, I quickly reached an agreement to buy her.”

Catch up with the owner of Scintilla Maris, Erik Vonk and BOAT International’s editor-in-chief Stewart Campbell at this year's Explorer Yachts Summit (13 November 2024 at the Yacht Club de Monaco) and discover the story of what really went into creating this one-of-a-kind yacht.

The way he talks, it sounds as if it were just yesterday that he shook hands on the deal. But it was in fact way back in 2006, firing the starting gun on a 17-year marathon which he is more than a little sad to have concluded. For much of that time, he was researching solutions, with the bulk of the yard work concentrated into just the last three years. “Now the journey is at an end,” he says. “This is a bittersweet moment for me.”

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

After decommissioning in 2006, Vertrouwen spent over 10 years gathering dust and rust at Damen Maaskant while her future was mapped out. Scintilla Maris now carries twin Zodiac Milpro MkIV tenders – serious 5.3m boats with 40hp Yamaha outboards

Fittingly, it is a journey that started and finished at Damen Maaskant’s yard, where the boat was originally built. In fact, two of the longstanding yard workers involved in the recent refit remember working on her in 1986. “These are the most beautiful fishing boats that have been built – beautiful lines and rock solid,” remembers Co Melissant, who has risen to become yard foreman. “It was a strange idea that the fishing era would end for this vessel, but an exciting idea that she would be given a new purpose as an exploration yacht.”

DAMEN MAASKANT

DAMEN MAASKANT

“You can be doing 14 knots with full rudder, but she won't list,” the owner tells me, as the captain nods enthusiastically from the helm

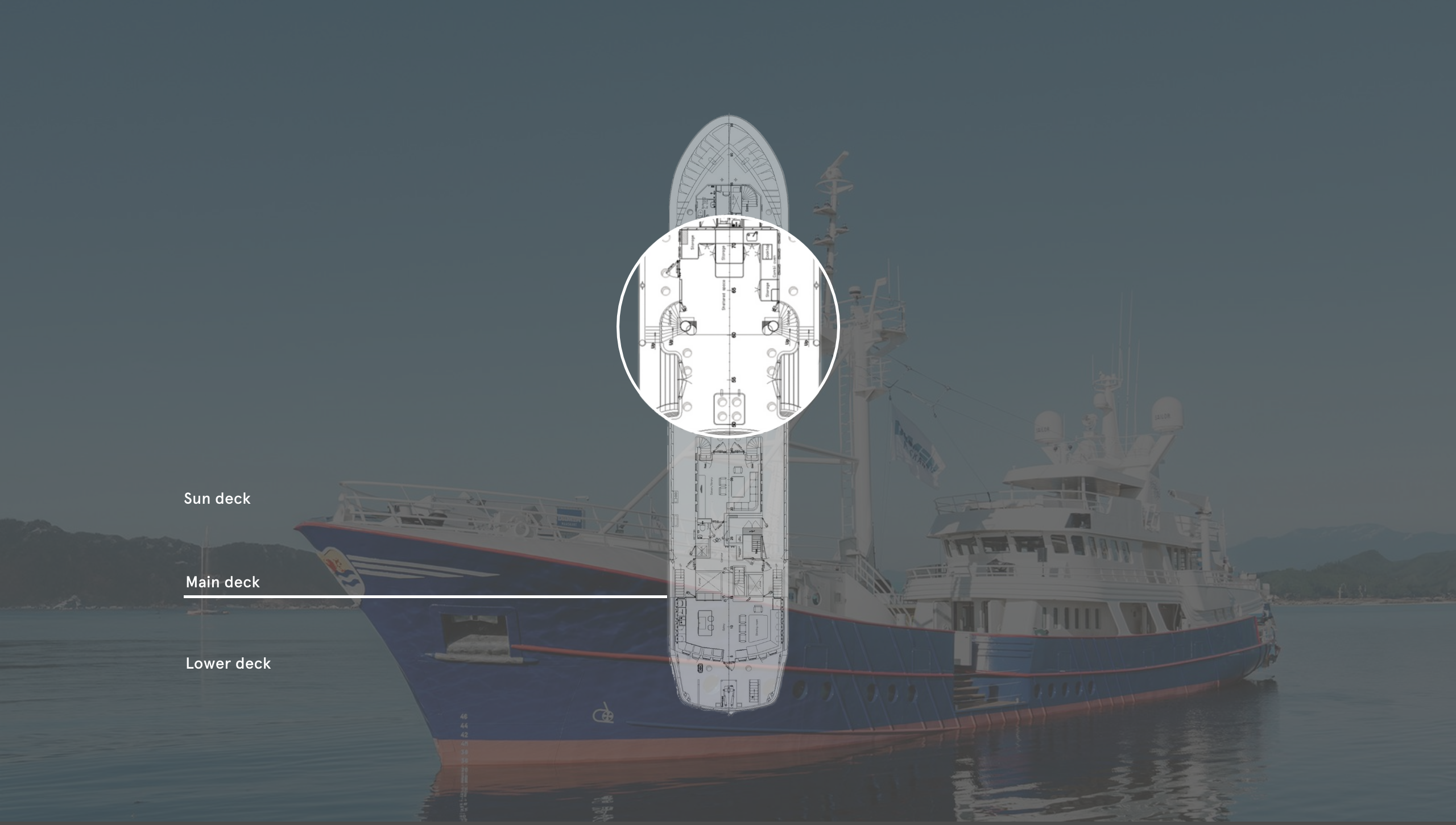

I call it a refit, but “rebirth” might be the better word, for the boat was sand-blasted right back to the bare hull and rebuilt from the inside out. The biggest challenges for the commercial yard were to design the engine room so that all the equipment was easy to access, and to reach the necessary standard for a yacht interior finish. “We have an ecosystem around the shipyard with subcontractors and suppliers who have the knowledge to set high standards and we have achieved this together,” says project manager Joris Saat. “Through direct contact with them we reached the standard agreed upon by the client.”

DAMEN MAASKANT

DAMEN MAASKANT

Rarely can a client have been so involved in a project. He had already been through the process with a smaller boat – a 25-metre tug he rebuilt largely with his own hands – so he had a clear sense of what was possible. “I’ve also spent a lot of time aboard big ‘white yachts’ and as a consumer, I have developed some very specific wishes,” he explains. “So, I did the design work and specification myself. The yard was always willing to chat when I came in with stacks of papers. They had the patience.”

It was a process that bore fruit, generating a bunch of unusual solutions, such as the midships platforms for accessing the water. “The problem with the beach club is that, however nice you make it, it is psychologically wrong,” declares the owner. “Having it at the back end isn’t right!”

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

Then there’s that cowling at the bow. On a high-seas trawler, this metal “pram hood” protects those working to store the fish from the pounding waves and wind-driven spray. But the owner wanted to open this space up, so the cowl had to be trimmed. “I spent two days marking out the cut line with black tape,” he says. “Each time I would climb back onto the dock to see how it looked.”

Scintilla Maris has retained the massive steel structures of her fishing masts, which supported the great hinged booms from which she dragged her nets. Intrepid souls can still climb the masts using the functional cage ladder welded to the starboard side. I’m interested to know whether the owner has been up there. “Oh yes,” he says. “You can get four chairs in the crow’s nest. It’s a lovely spot with wonderful views.”

A TASTE FOR THE HEAVY STUFF

A dive into the details on Scintilla Maris

Best known for building and repairing workboats, merchant vessels and naval ships, Damen Maaskant is the commercial arm of the family-owned group of Damen shipyards. While there is a division dedicated to yachting, the group has acknowledged a market demand for projects that fall outside the remit of superyacht refits associated with Damen Yachting. In this case the Damen Maaskant yard in Stellendam was able to bring its commercial and fishing shipbuilding experience to the leisure and refit sector.

Fishing boats from all around Europe have been coming here for decades for speedy repairs or wholesale upgrades. But now, with the construction of a new shed capable of taking a 60-metre vessel, the yard is aiming to handle two refits per year. Project manager Joris Saat showed me round a 45-metre project in for a 15-metre hull extension (yes, you read that right), and an entirely new interior.

“We’re close to finishing the new dock for the Mammoet boat mover, and we’ve got apartments for up to 40 crew just down the road, as well as bicycles for them to get around,” he says, adding: “We’re close to Rotterdam, but not so close the crew are distracted.” This veteran of numerous yacht projects from the biggest Dutch brands sure knows how to manage a successful refit.

On the raised foredeck below, there’s ample room for a big table and chairs or lounging furniture. And below that, in what was once a fish handling area, there is now an outdoor kitchen and bar that is the centre of the party on the day of my visit. It is covered and therefore protected, but left open on the aft side so that it doesn’t add to the gross tonnage.

But to imagine that this yacht is destined for a sunny life of casual Mediterranean socialising would be to make a grave mistake. Scintilla Maris is to test her go-anywhere hull, turning north for high latitudes. In fact, she has joined the EYOS Expeditions charter fleet, and will be available in Svalbard, Greenland and coastal Norway starting this spring.

Her explorer credentials become very clear as the owner draws my attention to the boxy relief running round the bulwark of the bridge deck in the form of three bands. “Those three ribs carry cooling water from two of the generators,” he explains. “That will stop any ice from forming and provide some warmth for those out on the bridge. It is the advantage of working with something that already exists – you can be a bit more creative.”

DAMEN MAASKANTThe decks have been covered in 40mm-thick Iroko planking – more sustainable than teak and a much better insulator

DAMEN MAASKANTThe decks have been covered in 40mm-thick Iroko planking – more sustainable than teak and a much better insulator

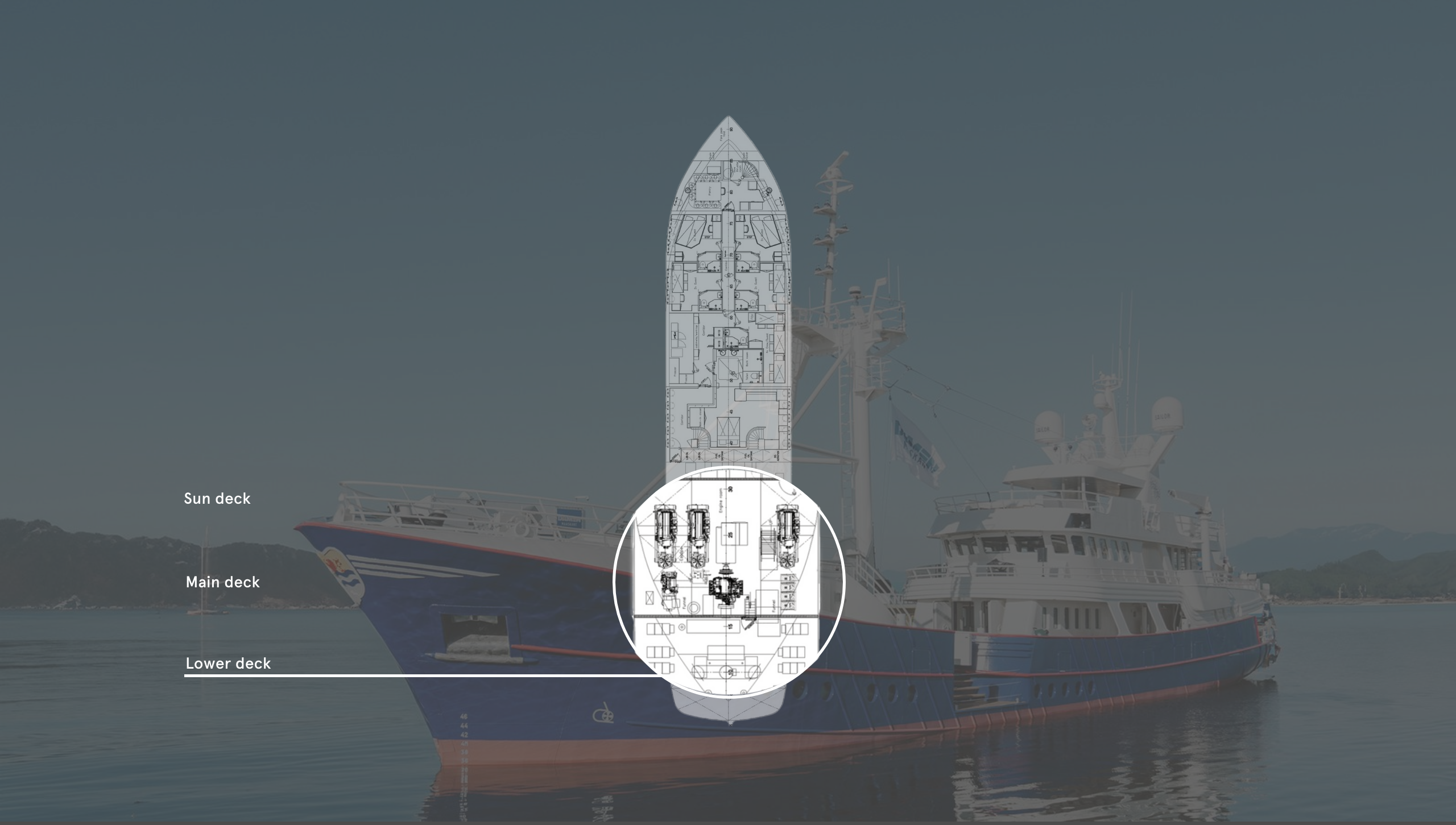

One of the bigger structural jobs involved extending the upper part of the superstructure around three metres aft, to fill more of the bridge deck. The owner shows me the faint knuckle in the side that betrays the join. At the same time, the aft deck below has been opened up for seating by replacing the bulwarks with a railing that makes the area brighter and breezier. Taken together, all these changes net out to reduce the original 570GT volume marginally below the magic 500GT mark. There’s still the small matter of the new sundeck above the wheelhouse, but this is all outdoor space and has no impact on the gross tonnage.

But there is another element to this rebirth, which only becomes clear if you explore below, poking into the large machinery room aft. In here are the muscular frames of three 585kW generators built on the Volvo D16 block. Where the ship’s original 4,400hp Deutz engine would have sat, there is now a small, efficient electric motor, packing 1,300kW of power. A 1MW battery bank will go in soon, and the owner is thinking about solar panels too. Sustainability is what this upgrade is all about – and the owner has strong views about it. “I think every owner should take a greater sense of responsibility,” he says. “If you’re one of the few that gets to own a great bit of equipment, you should make it as efficient as possible.”

Efficiency also means range, of course, which is core to the mission of Scintilla Maris. Her 154,000-litre fuel tankage gives her an extraordinary 9,000 nautical miles at a steady cruising speed of 9 knots. The boat can maintain this using just a single generator, giving lots of headroom for the owner’s planned expedition through the Northwest Passage.

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

In the master cabin, the design is centred around a vertical sight line. In the kitchen-dining space, finishes are highly durable, using high-pressure laminates and PVC and robust outdoor fabrics inside, making the interior “diver proof ”, which is important in an explorer

At one point in our triumphal cruise along an oily-smooth Haringvliet, I become aware that the boat has turned around and is heading for home. It's not because of a slow down that I notice, or because the boat has rolled on the turn; it’s because the sun has swung round to impinge on my side deck. “You can be doing 14 knots with full rudder but she won’t list,” the owner tells me on the bridge, as the yard captain nods enthusiastically from a very comfy seat at the helm. Before us are arrayed three vast 55-inch flat screen displays, providing an immersive read-out on every element of the boat’s navigational and operational status. “Based on my being a pilot, I’m always looking for optimal situational awareness,” he continues.

DAMEN MAASKANTThe decking makes for a more pleasant experience when barefoot in the tropics

DAMEN MAASKANTThe decking makes for a more pleasant experience when barefoot in the tropics

Below decks, the owner has moved some of the original bulkheads to create a sense of space, and brought in Vripack for the styling. The main deck is the heart of the boat, with a bright saloon forward and a huge eat-in galley aft. “We designed it to look like a country kitchen, where you can live as a guest,” the owner explains. There’s no stainless steel here; no professional appliances. Its island unit, induction hob and extensive work surfaces are as much for the owner or charter guests as for the crew. “Comfortable but not luxury,” the owner summarises.

DAMEN MAASKANTFishing is a strong familial link for the boat's owner – his ancestors have roots as fishermen on the Netherlands’ North Sea island of Texel, where some of his relatives still ply local waters

DAMEN MAASKANTFishing is a strong familial link for the boat's owner – his ancestors have roots as fishermen on the Netherlands’ North Sea island of Texel, where some of his relatives still ply local waters

It’s the same on the cabin deck below, which runs to five good-sized guest cabins and room for up to seven crew.

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

DAMEN MAASKANT

The spectacular “skylights” are hatches that would have been used for moving fish boxes up out of cold storage and onto the quay. A flexible fifth cabin makes good use of an awkward space between the main and guest areas. With three singles, it lends itself to children, expedition guides or extra crew

In line with the authentic workboat looks, Vripack has avoided any flashy detailing. Matt white walls and wooden floors are lit by a smattering of indirect lighting and offset by some splashes of leafy green and terracotta upholstery. It radiates quiet quality.

The result is an interior that costs perhaps a tenth of a full-fat superyacht interior

The master cabin lies amidships, beneath two large glass hatches originally served for swinging the fish boxes up out of cold storage and onto the quay. “We focused on a vertical sightline rather than a horizontal one, which is of course a great opportunity – it’s special,” says Vripack co-creative director Marnix Hoekstra. “We wanted to emphasise the light going up because the port holes are high up, so it’s not easy to look outside when you’re in the owner’s stateroom.”

DAMEN MAASKANT

DAMEN MAASKANT

Vripack drew inspiration from the many commercial yacht interiors it has produced over the years, opting for simplicity and extreme durability, according to Hoekstra. “It’s not even commercial proof, but diver proof, which is the next level,” he says. “It’s a combination of high-end, high-pressure laminates [HPL] all with beautiful, rounded corners, which we specifically moulded. Inside we used outdoor furniture fabrics, which are much more durable. The Iroko decks continue inside with the PVC flooring. You don’t have to take off your shoes on this boat!”

DAMEN MAASKANTThe aim was “comfortable but not luxury”, according to the owner

DAMEN MAASKANTThe aim was “comfortable but not luxury”, according to the owner

The result is an interior that cost perhaps a tenth of a full-fat superyacht interior, Hoekstra adds. It respects the DNA of the trawler style, the owner’s requirement for comfort and Damen’s in-house capabilities. It may have taken nearly two decades to complete, but the soul of the boat and of her owner have been enhanced by the experience. And that, in a nutshell, is the key to the undoubted success of the Scintilla Maris project.

First published in the February 2024 issue of BOAT International. Get this magazine sent straight to your door, or subscribe and never miss an issue.

The crow’s nest has room for four chairs for an elevated view

The cowl at the bow was cut back to the owner’s specifications

The outdoor kitchen and bar is a key entertaining spots

There are five guest cabins and room for seven crew

The engine room was designed so all equipment is easy to access

LOA 45.6m | Gross tonnage |

LWL 42m | Engines |

Beam (max) 9m | Generators |

Draught 4.9m | Speed (max/cruise) |

Range at 9 knots | Owners/guests 10 |

Fuel capacity | Crew 8 |

Tenders | Classification |

Freshwater capacity | Construction |

Naval architecture | Builder/year (original) |

Exterior styling (refit) | Builder/year (refit) |

Interior design (refit) | Refit design |

For charter | |