FLIGHTS OF FANCY

On board Magic Carpet e: Sir Lindsay Owen-Jones’s revolutionary Maxi yacht

Sam Fortescue believes Sir Lindsay Owen-Jones’s new Magic Carpete, with its sculpted sheer line, go-go-gadget keel, lifting rudders and fully electric power train, leaves convention floundering in its glistening wake

CARLO BORLENGHI

In the rarefied world of maxi yacht racing, few names carry as much weight and respect as that of the Magic Carpet campaign. Across the three previous yachts to carry the name, owner-driver Sir Lindsay Owen-Jones has racked up dozens of wins, including line honours in the Giraglia offshore race and no fewer than seven victories in Porto Cervo. Now he has just launched his fourth Magic Carpet and reckons the yacht is going to shake up the maxi scene. Again.

CARLO BORLENGHIThe topsides would have been lower for a pure racer like Comanche, but owner Lindsay Owen-Jones insisted that there should be headroom below for comfortable cruising

CARLO BORLENGHIThe topsides would have been lower for a pure racer like Comanche, but owner Lindsay Owen-Jones insisted that there should be headroom below for comfortable cruising

Magic Carpete marks a clear departure from his previous Wallys, however. There’s a new designer, Guillaume Verdier, and a new yard, Persico, whose carbon-fibre layup was so accurate that the boat is 10 tonnes lighter than her predecessor.

She is stuffed with clever engineering that serves to increase performance while allowing the yacht to go fully electric – for her voracious hydraulic systems and for propulsion. And to top it all, this racing maxi has a beautiful three-cabin interior that permits her to cruise.

CARLO BORLENGHIThere is a large hatch just forward of the mast, down which sails can be hauled using a “string drop” system for repacking below

CARLO BORLENGHIThere is a large hatch just forward of the mast, down which sails can be hauled using a “string drop” system for repacking below

Owen-Jones counts Wally founder and visionary Luca Bassani as a personal friend and says it was a tough decision to move on. “It wasn’t our choice,” he admits. “Wally wasn’t really interested in a one-off, highly risky project. Luca would have liked this boat to have had ‘Wally’ written on the side and, for sure, there’s something of him in it.”

CARLO BORLENGHI However, the use of high-end roller furling sails has made this redundant – the team can accomplish a flawless furl and drop the whole assembly onto the deck in seconds

CARLO BORLENGHI However, the use of high-end roller furling sails has made this redundant – the team can accomplish a flawless furl and drop the whole assembly onto the deck in seconds

Similarly, Owen-Jones says he has enormous respect for Jim Pugh, who designed Magic Carpet 3 . “But we explored with them various possibilities and felt that they hadn’t gone as far away from the original concept as they could have done.”

“These developments break out of the cycle of small iterative improvements”

Verdier, who has had a hand in numerous projects from the flying AC75 monohull of the America’s Cup to the giant Ultim trimarans that roam the world’s oceans, was another story. Project manager Ed Bell chimes in at this point. “I mean, it was something very different from Verdier. I think we all just loved the ideas he put forward.”

The evidence is there to see when I arrive in Magic Carpete ’s home port of Saint Tropez for sea trials, where she lies alone in the early spring emptiness of the old harbour. Immediately obvious is the pronounced reverse sheer – the unusual way in which the deck arches up amidships before plunging towards bow and stern.

There’s lots of “topography” to this boat – the gently curved flush deck runs from the companionway to the bow, but it has been hollowed out like a giant spoon at the foredeck.

“The curved sheer is pure engineering,” says Axel de Beaufort, who partnered on the design team. “There’s no styling here. It’s the shape you need to withstand the load, just like a beam. The scoop at the bow helps to manage the airflow at the bottom of the sail.”

CARLO BORLENGHI

CARLO BORLENGHI

What I can’t see straight away is one of the yacht’s key features and secret weapons: the large swing keel, which allows it to switch from a race-winning draught of 7.1 metres to a more harbour friendly 4.6 metres. We’re not talking some sort of giant centreboard here, but a 9.6-tonne bulb keel which swings up and back. Oh, and it also cants 45 degrees on either side. It is an engineering first on a boat this size.

“We wanted to avoid a vertically lifting fin as this would have required a heavy structure with a high centre of gravity which in turn would compromise performance,” Verdier tells me later. “The solution was to create a keel that reduces its draught by swinging 60 degrees aft like a centreboard, but where the keel bulb remains parallel to the waterline. The operation can be performed in two minutes.”

CARLO BORLENGHI

CARLO BORLENGHI

CARLO BORLENGHI

CARLO BORLENGHI

The windward rudder can lift to clear the water and reduce wetted surface upwind

CARLO BORLENGHI

CARLO BORLENGHI

The next day, Bell shows me the mechanism, which is visible through a well just forward of the saloon. There’s a giant hydraulic cylinder that pumps the keel back and another one that cants the whole assembly.

By the end of the afternoon, the wind has risen to 18 knots and we’re reaching at 20 knots with me spellbound at the wheel

A third element keeps the bulb horizontal as the keel swings, so that its point doesn’t punch a hole through the hull. The bare bones of the boat are exposed here, in gleaming carbon fibre. Through another structural opening, brightly coloured hydraulics whine and groan.

The efficacy of the design is soon clear, as our first outing delivers a nice little northeasterly, funnelling down into the Golfe de Saint Tropez and strengthening as the afternoon warms up.

BENOIT LINEROFor racing, the team swaps the cork-lined sole boards below for lightweight carbon ones. Wardrobe and clothes storage can also be removed from the cabins, saving perhaps 200kg all told

BENOIT LINEROFor racing, the team swaps the cork-lined sole boards below for lightweight carbon ones. Wardrobe and clothes storage can also be removed from the cabins, saving perhaps 200kg all told

After a quick briefing from Captain Danny Gallichan, the crew leaps into action, raising first the main then the jib and locking the halyards off. The sails start to generate lift and you can feel the acceleration as Magic Carpete finds her stride.

The efficacy of the design is soon clear, as our first outing delivers a nice little northeasterly, funnelling down into the Golfe de Saint Tropez and strengthening as the afternoon warms up.

BENOIT LINEROFor racing, the team swaps the cork-lined sole boards below for lightweight carbon ones. Wardrobe and clothes storage can also be removed from the cabins, saving perhaps 200kg all told

BENOIT LINEROFor racing, the team swaps the cork-lined sole boards below for lightweight carbon ones. Wardrobe and clothes storage can also be removed from the cabins, saving perhaps 200kg all told

After a quick briefing from Captain Danny Gallichan, the crew leaps into action, raising first the main then the jib and locking the halyards off. The sails start to generate lift and you can feel the acceleration as Magic Carpete finds her stride.

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

Designer Axel de Beaufort said he was inspired by the film 2001: A Space Odyssey to approach the design like a spacecraft. For instance, instead of square doors, there are structural openings in the bulkheads.

In no time, we’re foaming off upwind at 12 to 13 knots, the North 3Di sails close hauled and making around 45 degrees off the wind. By the end of the afternoon, the wind has risen to 18 knots and we’re reaching at 20 knots of boat speed with me spellbound at the wheel.

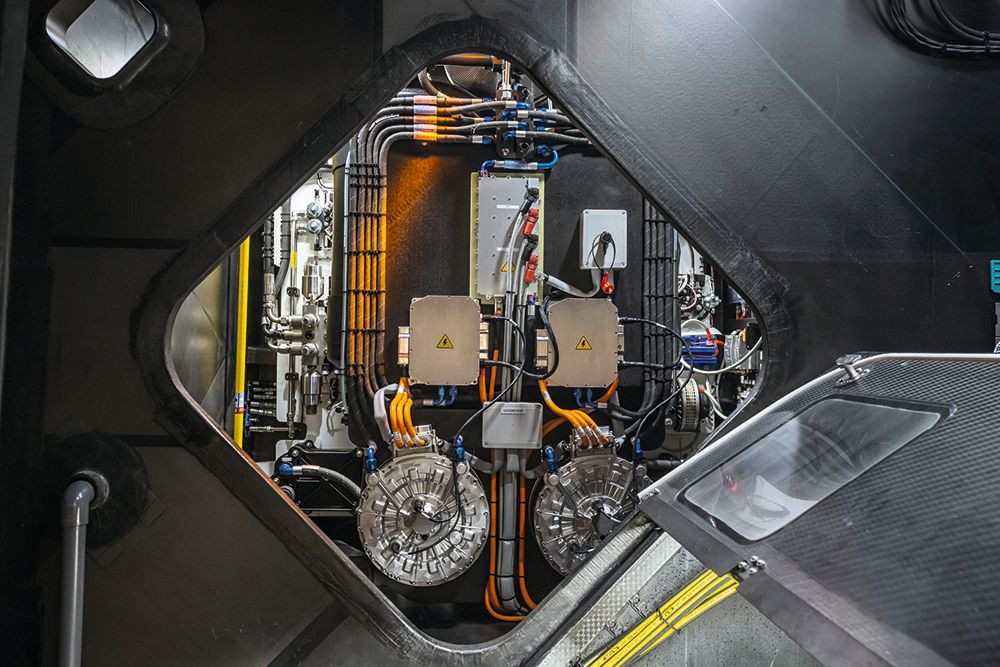

CARLO BORLENGHIThe boat’s hydraulics can be seen through a structural opening next to the keel. They are powered by two custom 220kW electric motors that get their energy from a 101kWh battery bank

CARLO BORLENGHIThe boat’s hydraulics can be seen through a structural opening next to the keel. They are powered by two custom 220kW electric motors that get their energy from a 101kWh battery bank

The helm consoles are surprisingly modest affairs, with just enough space to carry two B&G instrument read-outs. The pillar supporting it, however, is studded with buttons which keep our salty mainsheet trimmer busy as he reclines against the coaming. Captain Gallichan – who has been in command of every Magic Carpet ever built – stalks the pit with the keel controls buckled at his waist, like those remotes you see crane operators using.

MARCELLO PERSICO

CEO PERSICO MARINE

What were the most challenging elements of this build? One of the biggest challenges was delivering the exacting performance and aesthetic standards expected by a client like Sir Lindsay Owen-Jones. Achieving structural perfection, weight optimisation and seamless integration of systems in such a complex custom build required coordination across design, engineering and production at the highest level.

Explain your use of ATM technology in the build. One of the biggest breakthroughs at Persico was the use of an Automated Tape Laying Machine (ATM), a technology previously seen in the aerospace industry, but never before used on a yacht of this size. Aside from the lamination of the hull, every item was produced by the ATM, which offers huge benefits both to the engineers and the builders. The engineers can specify whatever fibre orientation is best for the task. The ATM can also lay up fibres around curves, something that is very hard to do by hand. The machine is more precise, uses less material and achieves a higher quality finish.

Its rollers can lay down fibres at six bar pressure, which means there is a much higher degree of laminate consolidation, allowing a much more efficient use of materials.

How did you hit the forecast weights so precisely? That comes down to two things: precise material control and process discipline. Using technologies like the ATM allowed us to reduce variability and human error. Every layer of carbon is placed exactly as designed, and that translates into very tight tolerances – something essential for meeting performance goals.

Is it fair to say that high-end boat building is becoming more machine-led? Machines enhance consistency and precision, but they don’t replace human expertise, especially when it comes to craftsmanship, problem-solving and innovation. The future is a balance: automation where it matters, and human skill where it counts most.

What were the most challenging elements of this build? One of the biggest challenges was delivering the exacting performance and aesthetic standards expected by a client like Sir Lindsay Owen-Jones. Achieving structural perfection, weight optimisation and seamless integration of systems in such a complex custom build required coordination across design, engineering and production at the highest level.

Explain your use of ATM technology in the build. One of the biggest breakthroughs at Persico was the use of an Automated Tape Laying Machine (ATM), a technology previously seen in the aerospace industry, but never before used on a yacht of this size. Aside from the lamination of the hull, every item was produced by the ATM, which offers huge benefits both to the engineers and the builders. The engineers can specify whatever fibre orientation is best for the task. The ATM can also lay up fibres around curves, something that is very hard to do by hand. The machine is more precise, uses less material and achieves a higher quality finish. Its rollers can lay down fibres at six bar pressure, which means there is a much higher degree of laminate consolidation, allowing a much more efficient use of materials.

How did you hit the forecast weights so precisely? That comes down to two things: precise material control and process discipline. Using technologies like the ATM allowed us to reduce variability and human error. Every layer of carbon is placed exactly as designed, and that translates into very tight tolerances – something essential for meeting performance goals.

Is it fair to say that high-end boat building is becoming more machine-led? Machines enhance consistency and precision, but they don’t replace human expertise, especially when it comes to craftsmanship, problem-solving and innovation. The future is a balance: automation where it matters, and human skill where it counts most.

He also controls another key feature of the yacht via a joystick on the starboard console. This is the so-called canard – a short appendage somewhere between a rudder and a keel positioned on the hull’s centreline just forward of the keel. Its purpose is to grip the water and prevent the boat from making leeway when the keel is canted to windward and can no longer do the job itself.

BENOIT LINEROThe simple interior, with furniture upholstered in a custom Hermès Horizons fabric, includes a saloon, two guest cabins and an owner’s cabin

BENOIT LINEROThe simple interior, with furniture upholstered in a custom Hermès Horizons fabric, includes a saloon, two guest cabins and an owner’s cabin

And as I’m about to discover, this canard is highly mobile. “See what you make of this,” Gallichan says to me with a twinkle in his eye. He twiddles the joystick and immediately, the bow starts rounding up, compass whirling. I correct hard with the wheel, unclear what’s happening. “Don’t fight it,” he counsels as he brings the stick back to the centreline and we settle back on our old course.

“We told the owner that we should treat the inside as a rocket”

The next day Owen-Jones expounds on the value of the feature. “Set it right and we actually make positive leeway going upwind,” he tells me with real delight. “We can gain three degrees on our heading instead of losing out.” This can also be used to advantage when tacking round a mark, but the team admit that more work is needed to understand how to mitigate the opposite effect in the gybe.

Where every other maxi on the water spends the day’s racing with the engine revving hard to drive the hydraulic packs, Magic Carpete is another thing altogether. She has a big 101kWh battery bank hidden under the saloon sole on the waterline, driving two custom-made 220kW electric motors that power the hydraulics.

It’s by no means silent, with the familiar whine of pumps as the load comes on, but it liberates the crew from the endless throb and vibration of the engine. A third electric motor propels the boat itself. Perhaps unsurprisingly for a man who counts motorsport as one of his life’s passions, Sir Lindsay and his team looked to Formula E when it came to developing both the motors and the batteries for Magic Carpete.

Williams Advanced Engineering, now called Fortescue Zero, is keeping the technical details a closely guarded secret, but Captain Gallichan says, “at the moment there is nothing comparable in the marine sector in terms of power density.”

BENOIT LINERO

BENOIT LINERO

The 150kW backup generator has not been needed, because the battery more than covers a full day on the water. There’s also some innovative thinking around the twin rudders. Mounted on huge titanium bearings with a ceramic race, a hydraulic cylinder can raise the windward rudder 1.5 metres to clear the water and reduce wetted surface upwind.

The marginal extra weight was deemed a worthwhile penalty for coaxing a little extra speed from the boat in light airs. Italian hydraulics specialist Cariboni drew on its America’s Cup experience to deliver swift and efficient hydraulics here and throughout the boat.

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

BENOIT LINERO

Taken together, these developments break out of the cycle of small iterative improvements. The team is hoping that it will yield impressive results on the race course in the coming year, although Owen-Jones doesn’t quite like to say it out loud.

“I’ve been taught to be superstitious by my Italian wife,” he says, smiling at his wife, Cristina, sitting opposite him in the cockpit, somewhat dressed for wintery conditions in a woollen bobble hat.

“We didn't try to hide the

structure of the boat”

By launching the boat in the autumn, even before the interior was in, they’ve been able to fit in a long winter of race training and feel confident of their abilities going into the first event of the season: PalmaVela in April. After that, it’s a quick succession – the European Championships in Sorrento, the Loro Piana Giraglia, the Maxi Yacht Rolex Cup and Les Voiles de Saint-Tropez.

“We’ve had four to five weeks of sailing prior to the first season – it’s not very often you get that,” says Bell. “The whole season will be a learning curve – a season of tweaking. But we’ve got a good, strong team and we’ll leave Saint-Tropez feeling ready for the racecourse.”

BENOIT LINERO

BENOIT LINERO

It’s not going to be a push-over, however. There are some exceptionally strong performers with well-established teams, including V, Galateia, Blackjack and Leopard 3. Some of it will come down to conditions, as well. Magic Carpete is optimised for the Med’s dominant low-wind conditions with that vast sail plan and deep keel. Her relatively narrow hull is designed to minimise drag going downwind, but in a blowy event like last year’s Giraglia, such advantages are quickly eroded.

Magic Carpete is optimised for the Med's dominant low-wind conditions with that vast sail plan and deep keel

It’s worth remembering, too, that this was not just a racing boat project. The clear brief from the off was to produce a yacht that could also be cruised for weeks at a time. And to that end, Axel de Beaufort was brought in to create the most beautiful possible interior for the least additional weight – a shade under two tonnes in the end. There’s a large saloon with a table and comfortable sofa, a well-equipped galley, two guest cabins and the large owner’s double, all upholstered in custom Hermès Horizons fabric.

BENOIT LINERO

BENOIT LINERO

“We took inspiration from 2001: A Space Odyssey and told the owner that we should treat the inside as a rocket,” says de Beaufort. “That means we removed cladding, replaced square doors with structural openings in the bulkheads. I glued wooden veneer to foam backing for the walls and used acoustic fabric on the ceiling, upholstering on frames instead of the usual panels. We didn’t try to hide the boat’s structure.”

In the end, the clear hope is that the undoubted innovations built into Magic Carpete will stimulate other maxi owners to follow suit. Although details of the developments were kept on the down-low by Bell and the rest of the team, he is certain that there are already yachts in stealthy build using the idea of the canting/folding keel and a slimmer hull.

CARLO BORLENGHI

CARLO BORLENGHI

“I reckon we’ve got about two years tops,” he confides. And I suspect that Owen-Jones would not mind so much, either, if his legacy were to galvanise a new wave of interest in the maxi class. It’s all there in the fact that he offered Magic Carpet 3 with a $100,000 discount if the buyer agreed to keep the boat in the Mediterranean for a season of racing.

“It was a good deal – all the set up and performance figures were there already,” he tells me. And presumably there is a strong desire to beat MC3 in the new boat, I enquire? Sir Lindsay nods and there is nervous laughter from some of the crew. Having campaigned in her for so long, they all know how hard she will be to beat.

First published in the July 2025 issue of BOAT International. Get this magazine sent straight to your door, or subscribe and never miss an issue.

LOA 30.48m | Generator 150kwh power cube |

LWL 29.42m | Sail area (upwind/downwind) |

Beam 7.2m | Sails North Sails 3Di |

Draught (Keep up/down) 4.6m/7.1m | Mast & boom Southern Spars |

Gross tonnage 94.GT | Rigging Aero Six |

Displacement 37 tonnes | Mast height 46m |

Electric motor 1 x E Helix | Tender 4.5m AB |

Fuel capacity 1,200 litres | Owners/guests 6 |

Freshwater capacity 1,888 litres | Crew 4 |

Construction Carbon fibre | Classification DNV |

Naval architecture | Builder/year |

Interior design | +39 035 520627 |